Nitrogen Generators

Features PLC/HMI Controlled Operation

- Operated by a reliable PLC control system with digital and optional analog outputs for remote monitoring and alarm capabilities.

- Provides the operator with continuous indication of column A, column B, inlet air & nitrogen outlet pressures and features an easy-to-operate touch screen graphical human-machine interface (HMI) which offers valuable information including:

- Power On Off

- Oxygen Purity

- Inlet & Outlet Pressure

- Online Column

- Service Required

- Run Hours

Communication

- Standard communication protocols include Modbus TCP communications via RJ45 ethernet port and 4-20 mA signal to monitor nitrogen purity.

- An upgradable SD card records the performance of the generator and data that can be downloaded to any PC for analysis.

Purity Dependent Energy Saving (PDES)

- With the optional employment of 2 oxygen analyzers, the PDES option allows additional energy saving to be attained by keeping the purity within a narrow band of the required value.

- Achieved by elongating the adsorption cycle and consequently saving valuable compressed air

Features

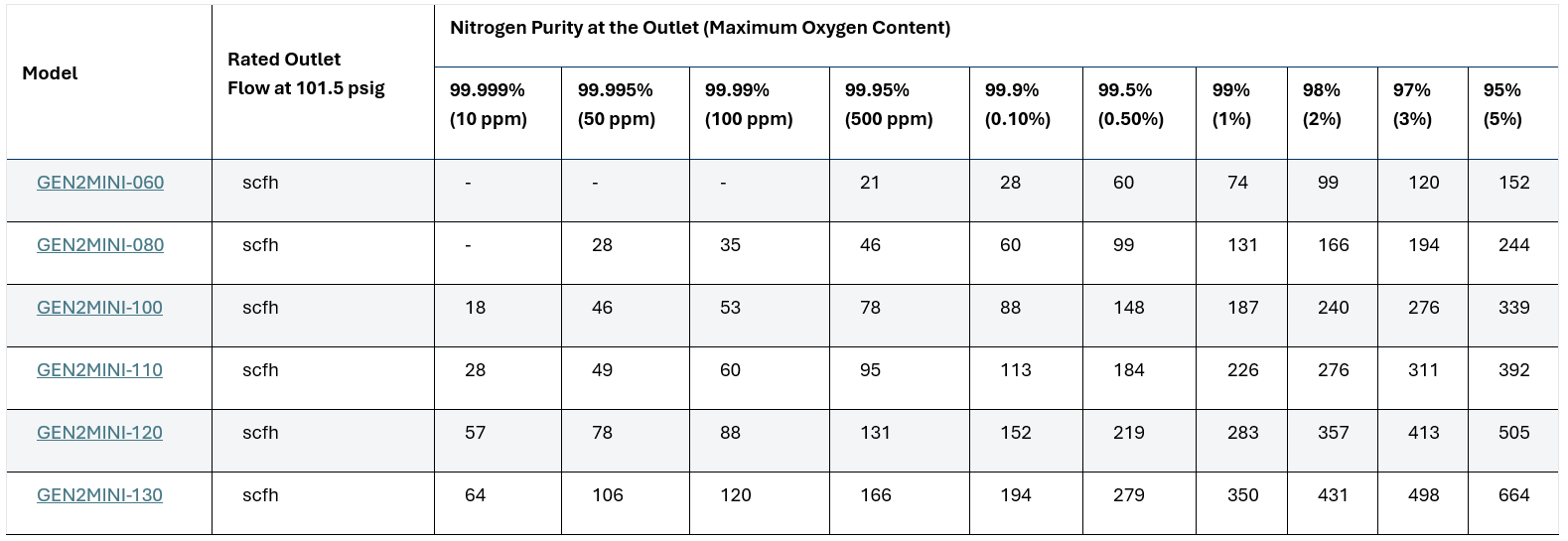

• Ultra compact design and wide range of flow rates, make it the

perfect generator for a variety of lower flow nitrogen applications.

• Significant cost savings over cylinder or liquid supply provides a

typical return on investment of less than 24 months.

• Uses pressure swing adsorption to produce a continuous,

uninterrupted supply of 95 to 99.999% purity nitrogen gas from

clean, dry compressed air.

• 100% functional tested with 2 year warranty.

• Eliminates safety concerns associated with transporting and

storing pressurized gas cylinders or liquid nitrogen.

• Reduces carbon footprint by eliminating gas delivery with positive

impacts on sustainability targets.

• eco-mode energy savings control reduces energy consumption

during periods of low demand.

• Optional integrated O2

analyzer and dew point sensors (N2

or inlet

air).

- Inlet Flow Controller

- Outlet Flow Controller

- Automatic Operation & PLC Control

- NEMA 12 Electrical

- NEMA 4 Electrical (optional)

- Touch Screen Operator Interface (optional)

- Tower Pressure Gauges

- Non-Lubricated High Cycle Valves

- Removable Stainless-Steel Screens

- ASME/CRN (GN2-75 and larger)

- Manifold Type Solenoid Valves

- Skid Mounted Component Packages

- Booster Compressor Packages

- Process Oxygen Sensor with Alarms

- Energy Saving Sleep Mode

- Automatic Purity Proof System